Rutuparna Rout • January 29, 2026

Procurement performance management: metrics that drive results

Last update: August 30, 2025

The biggest mistake a company makes is thinking everything is going well, and so, not reviewing its operations. It’s great if your team is working fast and productivity is high, but what’s going on behind the scenes? Now that’s something we need to find out. Procurement performance management helps businesses see how well their buying process works and where it can improve. This process enables you to track costs, supplier performance, and timelines, so you know your team is working to their full potential and saving money while building stronger business relationships in the long run. This blog tells you the know-hows of procurement performance, why managing and reviewing it is so essential, the key performance areas to monitor, and the best AI-powered solution to help optimize your processes.

What is procurement performance management?

Procurement performance management is the strategic process of checking and improving an organization’s procurement function. It involves defining, measuring, and improving performance against key objectives such as cost savings, quality, risk mitigation, and business value. A smooth, well-planned process reduces risks and maintains the company’s reputation.

What is the purpose of procurement performance management?

Procurement performance management is the ongoing process of monitoring, measuring, and improving the performance of your procurement activities. It helps organizations track spending, evaluate suppliers, and optimize their buying processes to achieve better results.

The core activities of PPM include:

- Evaluating supplier performance and reliability

- Finding opportunities to reduce costs

- Improving contract terms and negotiations

- Identifying and managing procurement risks

The main goal of PPM is to ensure your procurement department runs as efficiently as possible while minimizing risks and maintaining consistent, reliable supply chains.

Why PPM matters now more than ever:

Well-managed procurement performance leads to better outcomes for both procurement teams and the entire organization. According to Nicolas Walden, associate principal at the Hackett Group, effective procurement plays a crucial role in business success today. It serves as the foundation for business resilience in uncertain times, especially amid challenges such as supply shortages, market volatility, and rising costs.

In short, PPM transforms procurement from a simple purchasing function into a strategic advantage that drives value, reduces waste, and strengthens your company’s competitive position.

5 key Procurement performance management activities

Procurement Performance Management includes several key activities that help optimize your buying processes and achieve business goals. Here’s what each activity involves.

1. Tracking procurement performance

You can’t improve what you don’t measure. Start by understanding your current performance.

How to track effectively:

- Set Clear Goals – Use SMART objectives (Specific, Measurable, Achievable, Relevant, Time-bound) that align with company strategy

- Choose Key Metrics – Track cost savings, supplier quality, delivery times, and process efficiency

- Monitor Regularly – Review performance against targets to identify what’s working and what needs improvement

2. Supplier relationship management

Strong supplier partnerships are crucial for success. Good relationships deliver better quality, cost savings, reliable deliveries, and competitive advantages. Use supplier management platforms to automate routine tasks, so your team can focus on building trust and managing negotiations. Research shows that improving supplier collaboration is a top priority for procurement digitization.

3. Risk management

Procurement involves risks like supply disruptions, supplier failures, and material shortages. The pandemic showed that 70% of procurement leaders saw increased risk.

Manage risks in five steps:

Five steps to manage procurement risks:

- Identify – Spot potential problems (e.g., late deliveries)

- Analyze – Investigate root causes (financial issues, operational problems)

- Prioritize – Focus on the most significant threats first

- Mitigate – Take action (diversify suppliers, create backup plans)

- Document – Record insights and best practices for future use

4. Contract management

Contract management ensures everyone follows agreed terms. Poor contract management can cost businesses up to 9% of their bottom line. Monitor delivery schedules, pricing, service levels, and renewal rates to catch issues early. Good contract management helps prevent delays, quality issues, and compliance issues.

5. Continuous improvement

Procurement is an ongoing process. Markets change constantly, so your strategies must evolve too. Build a feedback culture by gathering input from your team and other departments. Use these insights to refine forecasting, adjust inventory levels, and improve communication.

What are the key factors of procurement performance management?

Procurement performance management helps companies track the effectiveness of their procurement processes. It improves efficiency, cuts costs, and builds better supplier relationships, making day-to-day operations smoother and brighter.

1. Tracks spending rate and savings

Knowing where you’re spending money helps improve the procurement performance process and removes any unnecessary expenses.

- Measure cost savings from supplier deals.

- Track cost avoidance and budgets.

- Monitor spend management KPIs for better control.

2. Checks vendor performance and helps with communication

When you have good suppliers and communicate with them regularly, it means smoother operations and higher product quality. Additionally, monitoring your suppliers’ performance helps prevent problems before they happen.

- Track supplier delivery times and quality.

- Measure supplier compliance with agreements.

- Identify supplier defects or delays.

3. Makes processes more efficient

With regular review, your procurement process becomes faster. It becomes simpler to understand, improves team collaboration, and prevents mistakes.

- Track purchase order accuracy and errors.

- Measure procurement cycle times from order to delivery.

- Monitor emergency purchases to reduce last-minute issues.

4. Improves contract management

Contracts ensure buyers and suppliers are on the same page about how their activities will proceed. Keeping terms in check and up to date through procurement contract management techniques helps avoid legal or financial trouble.

- Monitor contract compliance and deadlines.

- Track service levels and pricing agreements.

- Update records and document changes clearly.

5. Manages risks well

Planning for problems keeps procurement running smoothly even when things may derail.

- Try to identify potential risks beforehand, such as supplier failure or shortages.

- Prioritize which risks to address first.

- Set up mitigation plans and monitor results.

6. Keeps supplier relationships valuable

Good partnerships make procurement easier and open doors to better deals.

- Collaborate with suppliers on quality and delivery.

- Negotiate favorable terms and discounts.

- Share goals for long-term success.

How to measure procurement performance?

Procurement performance management helps teams clearly see what’s working for them and what they can improve on. The best way to do this is to set goals, track results, and conduct regular procurement audits to review data and know exactly where to focus. Here’s a step-by-step breakdown on how to measure performance in your sourcing processes.

1. Set clear objectives

You need to set clear goals for what you want your sourcing to achieve. They should match your company’s strategy, size, and budget. And to make these goals even more effective, they should be specific and realistic. First, you start small so you can grow from there. This serves as the basis for your procurement performance framework. Clear objectives guide teams and show what success looks like.

2. Select the KPIs and metrics that you will track

Choose the key indicators that matter most, which are the factors that you’ll be looking at. These can be cost savings, supplier reliability, lead times, and quality. For example, you can track the number of on-time deliveries or whether any products are defective. These metrics shape your procurement performance process and help evaluate efficiency.

3. Set realistic targets and keep moving upwards

It’s always good to have reasonable goals, but they should be realistic. To set sustainable goals, you can use past data, examine competitors’ achievements, or consider supplier expectations. Targets are helpful because they provide your team with an explicit reference.

4. Collect and review data, positive or negative

Each type of data is proper, regardless of whether it’s good or bad. You can gather accurate data from your suppliers or your teammates. Here, e-procurement tools and dashboards are helpful as they automate data collection and reduce manual errors. This also keeps your data precise and easier to read.

5. Review performance so you know where to improve

Check if the results you’re getting align with the target you set earlier. This will help you identify trends in your processes, spot issues, and adjust your strategies accordingly. You should also review your processes regularly, as this ensures your procurement process delivers real results.

6. Communicate with your team and improve

Effective procurement performance management involves sharing your progress with your team. To keep spirits high, tell them where they’re doing well and offer helpful tips to motivate them to keep improving. Highlight key areas, including cost savings, risks, and overall profits. With these insights and team feedback, you can work together to refine the procurement performance framework.

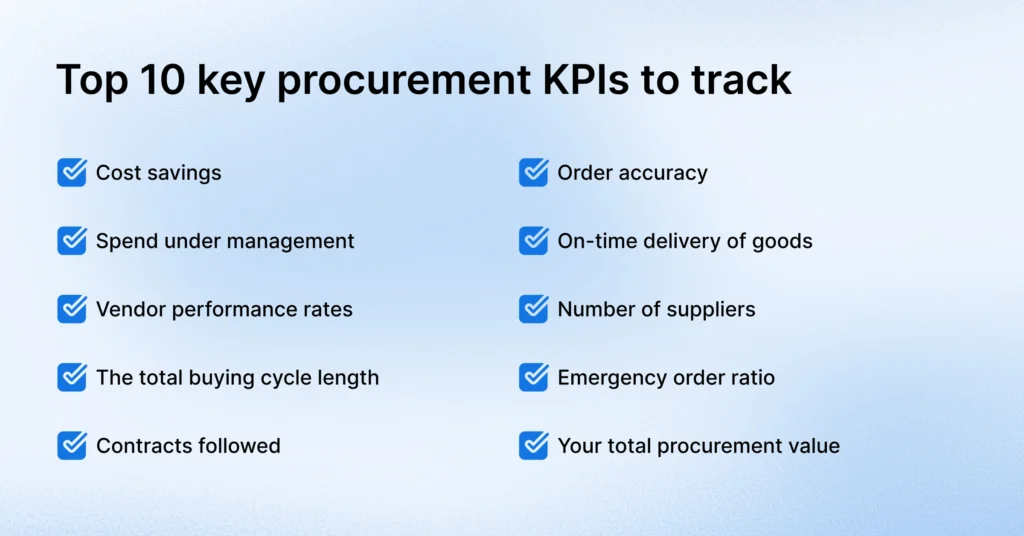

Top 10 key procurement KPIs to track

How do you know if you’ve covered every area of your process? With procurement performance management, you know the key procurement KPIs to monitor. Here are the most critical places you need to review to ensure you’re managing costs well, communicating with suppliers on time, and improving how you buy. These areas also show how well your team is working together. Here’s the list.

1. Cost savings

This area shows how much money your company saves on each order by negotiating better prices or finding cheaper vendors. And if the numbers are good, it’s a great indicator that you’re measuring procurement performance well.

2. Spend under management

This shows how well the company manages total spending through its procurement process. Basically, this doesn’t just cover order costs but shows how much the company has spent during the whole cycle. Here, higher numbers indicate better control over costs and contracts.

3. Vendor performance rates

In procurement performance management, it’s essential to check how often your suppliers deliver goods on time, whether they meet quality standards, and how fast they respond to requests. Always remember: if your suppliers are reliable, the whole process will be smooth.

4. The total buying cycle length

Just as the total procurement cycle cost is measured, the length of the buying process is measured, too. This starts when you place an order and ends when you’ve received all the goods. In this area, shorter times mean you’re able to wrap up fast and aren’t interrupted by delays.

5. Contracts followed

This KPI shows how compliant suppliers are with the agreed-upon contract terms, prices, and delivery dates. The higher the compliance rates, the better, as that shows supplier communication is good and there aren’t many problems.

6. Order accuracy

This performance indicator tracks whether purchase orders match the actual goods received. This involves checking PRs and invoices and matching the line items on paper to the ones you’ve got. Here, fewer mistakes save time and prevent extra costs.

7. On-time delivery of goods

Simply put, this KPI checks whether vendors are following deadlines or are slacking off. It’s a good way to keep them in check if they don’t deliver on time. Checking this helps you give them feedback, keeps projects on track, and reduces stress.

8. Number of suppliers

Since your company monitors multiple vendors, you’ll need to track them in one place and check their rates regularly. If you have fewer suppliers, you’re more at risk if multiple fail to deliver, and if you have too many, it isn’t easy to get good discounts.

9. Emergency order ratio

This metric shows you the number of purchases made outside the official process. This shouldn’t usually happen, as maverick spending significantly strains costs. So, if your numbers are low, that means your planning game is top-notch.

10. Your total procurement value

This calculates the value your procurement team brings compared to the money spent. A high return on investment indicates that your team is doing well and that their efforts are yielding good results. These procurement performance indicators help improve team collaboration and satisfaction.

The Power and Importance of Procurement Performance Management

Procurement performance management and tracking are so important as they help you improve your source-to-pay process. It gives businesses actionable insights into how efficient their processes are, how their cost savings are, and whether their supplier relationships are truly profitable. Closely monitoring this helps spot bottlenecks, make data-backed decisions to address them, manage spending rates, and ensure procurement functions align with business goals.

- Explore new areas for improvement: Tracking procurement helps you identify bottlenecks and missed savings. In procurement, even small changes can make a big difference. For example, Walmart saved $60 million by optimizing plastic bags and $20 million by changing floor wax.

- Make smarter decisions: Looking at procurement data shows you where you need to focus and, thus, gives you ideas on how to use resources better. It helps your team make more intelligent choices every day.

- Use money wisely: By reviewing procurement activities, you can identify cost-saving opportunities without significant changes to everyday processes. Minor tweaks in how you buy or manage suppliers can save a lot.

- See everything clearly: Procurement performance management gives a clear view of your supply chain, including supplier performance, buying strategies, and internal processes.

- Build trust with suppliers: When processes are transparent, it helps strengthen supplier relationships. For example, Unilever tracks raw materials to make sure sourcing is ethical and sustainable.

- Keep improving and working together: Measuring performance helps teams identify areas for improvement, brainstorm ideas, and fix problems faster through teamwork.

- Show value: Clear procurement performance indicators demonstrate the value procurement delivers to the business and why the procurement team is essential. It’s a morale booster for the company and positively impacts performance and growth.

Common challenges in procurement performance management & how to overcome them

Procurement performance management drives enterprise value when executed with rigor and stakeholder alignment. Here are the key challenges and solutions:

1. Poor Data Quality and Fragmentation

Problem: Data scattered across ERP systems, spreadsheets, and supplier portals makes consolidation and decision-making difficult.

Solutions:

- Implement data normalization and centralize information in a single source of truth

- Use AI-driven platforms to detect anomalies and standardize classifications

- Eliminate manual reconciliation through automated data integration

2. Misaligned KPIs and Business Objectives

Problem: Procurement focuses on cost savings while the business expects innovation, risk mitigation, or ESG progress.

Solutions:

- Engage cross-functional stakeholders when setting KPIs

- Translate corporate priorities into procurement metrics (e.g., sustainable supplier percentage, innovation index)

- Regularly review and adjust KPIs to reflect changing business goals

3. Inconsistent Reporting and Governance

Problem: Lack of clear ownership and standardized processes leads to reactive, error-prone reporting. Nearly 1 in 3 procurement functions lack consistent reporting standards.

Solutions:

- Define governance models with clear metric ownership and review cadences

- Deploy digital dashboards for real-time performance visibility

- Automate reporting to reduce delays and manual errors

4. Low Stakeholder Engagement and Buy-In

Problem: When procurement is seen as back-office, business units don’t support performance initiatives.

Solutions:

- Position performance management as a business value enabler

- Involve cross-functional teams in strategy and metric development

- Share success stories linking procurement performance to enterprise outcomes

5. Lack of Agility in Adapting to Change

Problem: Static scorecards and outdated frameworks prevent quick adjustments to market shifts. Agile teams significantly outperform during disruptions.

Solutions:

- Adopt platforms supporting scenario modeling and dynamic KPIs

- Build feedback loops for real-time market intelligence

- Keep metrics flexible without losing strategic focus

Addressing these challenges head-on enhances procurement’s ability to drive measurable value and strategic influence across the organization.

7 Best practices for sustaining procurement performance management

To sustain long-term value, establish KPIs, leverage structured data and technology for spend visibility, as well as conduct regular reviews with stakeholders and adaptability in your procurement performance management, implement these essential practices mentioned below:

1. Align with Business Strategy

Link procurement KPIs directly to your organization’s goals—whether cost reduction, sustainability, innovation, or supply chain resilience. This alignment earns executive support and demonstrates procurement’s strategic value.

2. Define Clear Ownership

Assign specific owners to each metric and integrate performance targets into individual and team objectives. Use responsibility frameworks (like RACI charts) to clarify who drives, approves, and monitors each KPI.

3. Automate Reporting

Deploy digital dashboards that provide real-time, transparent access to performance data. Automation eliminates manual errors and frees your team to focus on analysis and decision-making instead of data collection.

4. Create Continuous Feedback Loops

Treat performance reviews as ongoing conversations, not one-time reports. Conduct monthly or quarterly reviews with internal teams and suppliers to adjust KPIs based on current needs and market conditions.

5. Include Risk and ESG Metrics

Integrate supply chain risk, environmental impact, supplier diversity, and compliance measures into your performance scorecards. This provides a complete picture of supplier and procurement health.

6. Use Predictive Analytics

Move beyond reporting what happened to forecasting what’s coming. Analyze market trends, supplier patterns, and spending data to identify and address potential issues before they become problems.

7. Build Team Capabilities

Invest in training your procurement team on data analysis, strategic thinking, and digital tools. A skilled team is essential for effective performance management.

How Procol’s solution helps measure procurement performance

Procol’s AI-powered procurement solution helps companies track their entire buying process in a single, easy-to-use platform. It brings together everything you need, from tracking spending to checking vendor performance in one place, so you don’t have to juggle multiple tools.

With AI agents, you can monitor spend, track investments, and follow project progress in real-time, while the supplier performance page keeps you informed about supplier activities. The platform supports the complete procurement performance management framework, covering everything from planning and supplier management to results review and continuous improvement. You can easily track cost savings, measure deadline adherence, ensure contract compliance, and work toward goals such as sustainability and risk reduction. Procol integrates seamlessly with your existing tools and offers a simple dashboard that provides clear visibility into performance indicators, making it easy to share progress with your team or management.

Over 200 enterprises trust our innovative procurement solution, so whether you need to improve supplier relationships, reduce costs, or ensure your processes are efficient, Procol provides the information you need. Contact us today.

Conclusion

To stay ahead in today’s competitive market, you need to make your procurement process stand out. Procurement performance management is about buying smarter, saving money, and making your supplier relationships count. So, track the right metrics, review every result, and involve your team to drive improvement across the board. With the right tools, like Procol’s platform, it’s much easier to see what’s working rather than struggle with spreadsheets and last year’s performance notes. So, switch to the modern solution and give us a call accordingly.

Frequently asked questions

What is PMS in procurement?

A procurement management system (PMS) is software that helps organizations streamline and automate the procurement of goods and services. It typically includes modules for vendor management, contract management, purchase orders, and invoicing.

What are the factors affecting procurement performance?

Procurement performance is influenced by quality, cost, delivery, risk management, and supplier relationships.

What are the 5 P's of procurement?

The 5 P’s are Price, Product, People, Place, and Planning, which are the key areas to manage procurement well.

How do you check if procurement is effective?

The effectiveness of procurement is assessed by tracking KPIs like cost savings, supplier performance, cycle time, and compliance. These help companies know where their processes are bringing in the most value and where they need to improve.

Why is it important to review procurement performance?

Reviewing performance helps find areas to improve. It helps in making processes more efficient, controlling spending, reducing risks, and ensuring compliance with rules.

What are the 5 steps of performance management?

The steps are: Planning (setting goals), Monitoring, Developing (coaching teams), Reviewing (evaluating performance), and Rewarding (recognition of efforts).

What are KPIs in procurement?

KPIs are measurable values showing how efficient and well-planned the procurement and purchasing process is.

Why Traditional PPM Falls Short?

Traditional Procurement Performance Management often fails due to poor alignment across teams and initiatives. When procurement, finance, and sustainability departments don’t work together effectively, it creates serious problems that undermine the entire process.

Schedule a Demo

We’d love to hear from you. Please give us a call on +1 315-645-2799.

Explore more from Procol

Discover expert tips, how-to guides, industry insights, and the latest procurement trends.

Procurement orchestration: All you need to know in 2026

Explore the value of procurement orchestration, how it works, its benefits,...

Top 22 spend management KPIs to optimize procurement in 2026

Today’s business world has moved from just ‘buying’ to ‘managing spend’...

What is supplier diversity and why is it important?

In the modern corporate competitive world, where both market resilience and...