Procol • February 4, 2026

Sourcing strategies explained: Types, process, benefits, and examples

Last update: February 5, 2026

Sourcing strategies are important for creating effective, efficient, and resilient supply chains. In this blog, we will discuss the meaning of sourcing strategies, different types of sourcing strategies, including domestic versus global sourcing strategies, how to create a sourcing strategy, the stages in the strategic sourcing process, and the top ten procurement strategies. We will also discuss how technology is disrupting sourcing, the benefits of sourcing strategies, and some real-life examples on a global scale, before wrapping up with some key things to remember.

What are sourcing strategies?

Sourcing strategies are systematic approaches for finding and selecting suppliers or candidates to fulfill an organization’s needs, whether for goods, services, or talent. They are strategies that assist organizations to systematically and strategically identify, evaluate, and select suppliers to supply goods, services, or candidates. Sourcing strategies are designed to lead businesses in meeting prioritized objectives, such as achieving efficiencies that will lead to cost savings, improving the quality of products or services, managing supply chain risk, and creating long-term value. Sourcing strategies require organizations to do more than find the lowest total cost option; they require an examination of suppliers’ capabilities, reliability, compliance, sustainability, and ability to be aligned with the organization’s overall strategic goals, which will be essential for efficient and resilient procurement systems.

7 Step Strategic Sourcing Process

A sourcing strategy is crucial to ensuring that a business finds the right supplier, keeps costs under control, and makes all steps in the supply chain smooth. Thoughtfully creating a sourcing serves to support, once more, business objectives. A well-thought-out sourcing strategy can help an organization get better at assisting its objectives for quality improvement, risk management, and developing long-term value. Here’s a quick look at how to develop a sourcing strategy:

Understand when, how much, and where sourcing money is going and the effectiveness of those suppliers, and what the gaps are.

1. Develop clear objectives

Develop set goals, like cost savings, quality improvement, risk management, or sustainability.

2. Segment suppliers

Segment suppliers on suppliers that are critical, spend, allocation, and performance, to focus a whole lot of time on strategic relationships.

3. Conduct market research

Look into supplier capabilities, pricing behaviour, and overall category best practices.

4. Choose the sourcing approach

Select for a single, multiple, or global sourcing approach based on defined risk appetite and cost-to-supply requirements.

5. Develop the supplier engagement plan

Establish a clear policy on supplier communications, performance expectations, and what collaboration may look like.

6. Implementation

Implement the sourcing plan with all of the proper steps, processes, contracts, and monitor.

7. Monitoring and continually improving our sourcing strategy

Monitor performance, evolve, accept that markets change, and monitor and improve regularly.

A solid sourcing strategy is a key factor in successful procurement and supply chain management. Organizations can lower costs as well as enhance their supplier relationships, mitigate risk, and alter course as market needs change. With ongoing assessment and improvement, a sourcing strategy can remain relevant to business needs and provide long-term, sustainable results.

What is the difference between strategic sourcing and traditional sourcing?

Understanding the difference between traditional sourcing and strategic sourcing is crucial for organizations that want to use procurement efficiently and to create long-term value. Whereas traditional sourcing focuses on relatively short-term needs, costs, and solicitations, strategic sourcing considers how to leverage supplier relationships, risk management, and develop procurement objectives that align with overall business needs.

| Strategic sourcing | Traditional sourcing |

|---|---|

| Short-term procurement, lowest price. Focuses on immediate needs rather than long-term value. | Long-term value, cost savings, and risk management. Plans procurement strategically to align with business goals. |

| Orders are placed as needs arise without detailed analysis. | Decisions are based on spend analysis, market trends, and supplier performance. |

| Suppliers are treated as vendors for one-off purchases. | Builds long-term partnerships for reliability, innovation, and shared benefits. |

| Cost and availability. Main focus is on getting items quickly and cheaply. | Total cost of ownership, quality, risk, and sustainability. Decisions consider long-term impact and overall value. |

| Basic ordering and supplier selection with minimal planning. | Structured process: market research, supplier segmentation, negotiation, implementation, and continuous improvement. |

To summarize, regular sourcing is reactive and cost-oriented and deals with functionality or commitment for immediate needs, while strategic sourcing is proactive and value-oriented and can help organizations achieve lasting savings, better quality experiences, and sustainable supply chains. You should choose one sourcing strategy or the other based on your organization’s objectives and your procurement priorities.

Trends in strategic sourcing

Strategic sourcing is no longer limited to cost savings; it has evolved into a holistic approach that supports efficiency, innovation, and resilience. With rapid technological changes and increasing global uncertainties, organizations are rethinking their procurement strategies. Here are the five most important trends shaping the future of strategic sourcing.

1. Digital transformation in sourcing

Technology is transforming how companies manage sourcing and procurement. Tools powered by artificial intelligence, automation, and analytics streamline vendor selection, monitor performance, and reduce manual errors. Digital sourcing platforms provide real-time data, improve decision-making, and increase efficiency, enabling organizations to respond faster to changes in demand and supply chain conditions.

2. Focus on sustainability and ESG compliance

Sustainability is now a central theme in sourcing decisions. Businesses are partnering with suppliers who follow ethical practices, reduce emissions, and adhere to environmental, social, and governance (ESG) standards. Green sourcing not only strengthens brand reputation but also ensures regulatory compliance and meets customer expectations for socially responsible business practices.

3. Supplier collaboration and partnerships

Modern sourcing emphasizes strong partnerships with suppliers instead of transactional relationships. Organizations work closely with suppliers to drive innovation, ensure quality, and secure a reliable supply. This collaborative approach fosters trust, creates long-term value, and enhances resilience, as suppliers are more engaged and committed to helping businesses succeed in competitive markets.

4. Increased use of data-driven insights

Data analytics plays a critical role in strategic sourcing today. By analyzing spend patterns, supplier performance, and market trends, businesses can make smarter decisions. Predictive insights help companies negotiate better contracts, identify risks, and forecast demand. Data-driven sourcing strengthens financial control while improving overall efficiency and competitiveness in procurement strategies.

5. Risk management and supply chain resilience

Unpredictable disruptions such as geopolitical tensions, pandemics, and natural disasters have forced businesses to prioritize resilience. Companies are diversifying suppliers, nearshoring, and adopting contingency planning. Strategic sourcing now focuses on reducing dependencies and building agile supply chains that can withstand shocks while ensuring uninterrupted business operations and customer satisfaction.

What are the stages of the strategic sourcing process?

A structured strategic sourcing process can help organizations improve their procurement process, lower costs, and develop better supplier relationships. By following a logical sequence of phases, institutions can better assess their needs and wants, make good decisions, minimize risks, and find long-term value.

1. Clearly state business needs

The first stage of strategic sourcing is clearly stating business needs. This involves identifying required goods or services, setting quality standards, defining volumes and timelines, and aligning with organizational goals. Engaging stakeholders ensures accuracy and prevents misalignment, creating a strong foundation for effective supplier evaluation and long-term procurement success.

2. Spend analysis

Review historical spending to understand patterns of spend, hotspots of spend, and potential opportunities for savings.

3. Market research

Analyze industry trends, supplier capabilities, and market risks to make informed sourcing decisions. This helps organizations understand pricing benchmarks, innovations, and potential disruptions.

4. Supplier segmentation

Rank suppliers based on spend, importance, and performance to focus your organization’s sourcing activities properly.

5. Develop a sourcing strategy

Establish sourcing targets, determine sourcing methods, and develop the plan to engage suppliers.

6. Supplier identification

Research suppliers, develop a shortlist, and identify suppliers who provide services and/or products that your business needs.

7. Request for proposal (RFP) / quotation (RFQ)

Prepare and send structured RFPs or RFQs to shortlisted suppliers. These documents capture detailed supplier capabilities, pricing, and compliance information.

8. Evaluation and selection

Assess supplier responses against criteria like cost, quality, risk, and cultural fit. This ensures only the most capable and reliable vendors are chosen.

9. Negotiate and contract

Finalize pricing, terms, and service-level agreements. Effective negotiations secure cost savings while contracts ensure clarity and protect organizational interests.

10. Implementation and continuous improvement

Onboard suppliers, evaluate supplier performance, and adapt and change strategies to pursue value creation.

Following these 10 stages ensures that strategic sourcing is a structured, proactive process rather than a reactive one. Organizations can achieve cost efficiency, improve supplier performance, reduce risks, and create sustainable value for the business over time.

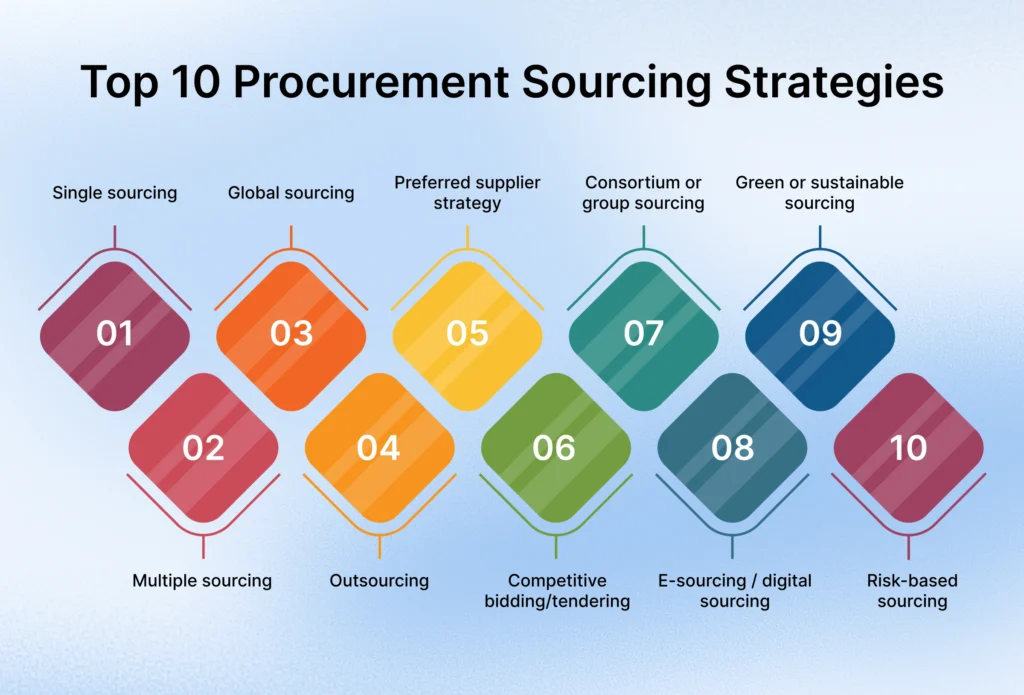

Top 10 procurement sourcing strategies

Effective sourcing strategies help organizations reduce costs, manage risks, and build strong supplier relationships. By choosing the right approach, businesses can improve efficiency, ensure supply continuity, and drive long-term value. Here are the top 10 procurement sourcing strategies:

Single sourcing

Relying on one supplier ensures consistent quality, strengthens partnerships, and simplifies management, but increases dependency risk.

Multiple sourcing

Using several suppliers reduces supply risks, encourages competitive pricing, and provides alternatives in case of disruptions.

Global sourcing

International procurement helps get cost advantages, advanced technologies, and other markets that enhance competitiveness and innovation.

Outsourcing

Delegating non-core procurement or production activities to external experts allows focus on strategic business priorities and efficiency.

Preferred supplier strategy

Long-term partnerships with selected suppliers improve reliability, collaboration, and often result in better pricing and service.

Competitive bidding/tendering

Inviting multiple suppliers to submit bids ensures transparency, encourages competition, and helps achieve optimal costs.

Consortium or group sourcing

Pooling resources with other organizations increases buying power, lowers costs, and strengthens negotiation leverage with suppliers.

E-sourcing / digital sourcing

Online sourcing platforms streamline procurement, improve supplier visibility, and accelerate sourcing decisions efficiently.

Green or sustainable sourcing

Selecting suppliers who prioritize environmental stewardship fosters sustainability, reduces environmental impacts, and supports corporate social responsibility goals.

Risk-based sourcing

Sourcing offers the consideration of financial, geopolitical, and operations risks in supplier selection by ensuring continuous supply and reducing the disruption of supply chain operations.

The maximum benefit of sourcing and selection depends on organizational needs, tolerance levels for risk in the supply chain, and placement of the sourcing strategy in the culture of the organization. A successful strategy means continuous cost reduction and improved supplier performance; it also enables the organization to have a more resilient, sustainable, and value-based procurement process.

How technology is transforming strategic sourcing

Technology is transforming the way organizations approach strategic sourcing by enhancing value for money through more efficient, transparent, and data-driven procurement processes. E-sourcing platforms, spend analytics, supplier management software, and artificial intelligence enable companies to identify opportunities to save costs, track supplier performance, manage risk, and provide insights, while process automation puts an end to manual and inefficient procurement processes. Automation also frees up procurement to focus on strategic instead of transactional work.

Digital dashboards offer real-time visibility to support quicker and more informed decision-making, and collaboration tools improve communication with suppliers. Technology offers more seamless negotiation, better relationships with suppliers, and improved supply chain responsiveness and agility. Essentially, technology enables organizations to take a more strategic, value-focused, and proactive approach to sourcing than has typically been the case.

Top 8 benefits of strategic sourcing technology

There is no doubt that investing in strategic sourcing technology is critical to modern procurement. With these tools, an organization can further streamline its sourcing procedures, improve its supplier management capabilities, and make better data-driven strategic sourcing decisions that create value for the long term. By leveraging the competitive advantage gained by using technology, purchasers can enhance their organizational efficiencies and potential cost savings while advancing their sourcing strategy.

1. Cost savings opportunities

Cost-saving opportunities are identified by spend analyses, supplier comparisons, and by making optimal sourcing decisions.

2. Improved supplier performance

Monitor supplier measurements, ensuring suppliers are on time, compliant with quality, and performing at a consistent level.

3. Increased transparency

Enhance visibility into your procurement processes, contracts, and supplier documentation to hold your organization accountable.

4. Risk mitigation

Monitor your supplier risks, market trends, and geopolitical supply risks to mitigate disruptions to your supply chains.

5. Faster decision-making process

The source could analyze real-time data and identify the best sources, pricing, and negotiate with suppliers within time frames that would not have been possible before.

6. Process automation

Automated rfp’s, approvals, and reporting processes will reduce manual tasks and enhance your team’s capabilities in sourcing, procurement, and strategy.

7. Enhanced communication and collaboration

Digital platforms can enhance communication with suppliers, and better collaboration can turn your relationship with a supplier into a long-term partnership.

8. Data-driven insights

Advanced analytics support strategic planning and predictive future forecasting, and develop sourcing strategies that lead to continuous improvement.

Strategic sourcing technology empowers organizations to make smarter, faster, and more strategic decisions. By adopting these tools, businesses can optimize costs, reduce risks, enhance supplier relationships, and maintain a competitive edge in today’s complex supply chain environment.

Global sourcing strategy

Global sourcing strategy involves purchasing goods, services, or materials from global suppliers to minimize costs, benefit from advanced technology, and expand market presence. Through global sourcing, organizations can diversify their suppliers and create a more efficient supply chain, drive quality improvement, and reduce single-source supplier dependency. While implementing this strategy means establishing relationships with suppliers across country borders, it can pose risks. Time is being removed from the supply chain, and managing many suppliers imposes certain risks in coordinating. For any global sourcing strategy, organizations must consider supplier resources, technology and capabilities, geopolitical framework, the global supply chain, logistics, legislative and trade policy, currency and currency risk, and overall political viability. Using global sourcing as a strategy can provide firms with a competitive advantage, greater flexibility and a quicker response to global changes, risk management and sustainability will also need to be addressed while keeping potential operational costs in mind.

Conclusion

After implementing procurement strategies, organizations rely on procurement to help optimize their supply chain processes, keep procurement costs low, mitigate risks, and build relationships within their supply chain. Organizations need to understand sourcing options, create a structured methodology toward strategy, use technology to source, and connect to global or sustainable sourcing. The end goal should be sustainability improvements, supply continuity, and efficiency improvements, as well as long-term value. It is paramount that strategic sourcing objectives be data-driven, allowing organizations the ability to guide their sourcing objectives and successfully manage supplier capacities and performance, along with remaining competitive in the marketplace.

Frequently asked questions

What factors should organizations consider when choosing between domestic vs global sourcing?

When deciding between domestic and global sourcing, companies should evaluate:

-

Cost vs total landed cost (including transportation, tariffs, duties, customs)

-

Lead time and reliability of delivery

-

Quality and compliance standards (domestic vs overseas regulatory differences)

-

Geopolitical and trade risks (e.g., tariffs, import restrictions, political stability)

-

Currency risk and exchange rate fluctuations

-

Supplier capabilities & capacity in foreign vs local markets

-

Sustainability, labor laws, and ethical concerns sometimes carry a higher compliance risk for global options.

-

What are the main risks of global sourcing and how can businesses mitigate them?

Global sourcing offers advantages (cost, access to broader supplier base, innovation) but also risks such as:

-

Supply chain disruptions (natural disasters, political instability)

-

Longer lead times & logistical complexity

-

Hidden cost escalators (currency, customs, transportation delays)

-

Quality/compliance differences across countries

-

Intellectual property protection & contractual enforceability

To mitigate these, companies can:

-

Diversify supplier base across geographies (dual or multi-sourcing)

-

Include clauses in contracts to cover quality, delays, and IP protection

-

Use strong supplier audits, certifications, and continuous monitoring

-

Build buffer stocks or safety inventory for critical items

-

Use technology for visibility & risk analytics

-

How can procurement teams measure the success of their sourcing strategy?

Key performance indicators (KPIs) that help track sourcing strategy effectiveness include:

-

Cost savings (actual vs baseline) and total cost of ownership

-

Supplier performance metrics (on-time delivery, defect rates, responsiveness)

-

Risk metrics (supplier disruptions, single-source dependency, supply continuity)

-

Compliance and sustainability indicators (ESG metrics, ethical sourcing, environmental impact)

-

Process metrics (cycle times, RFP turnaround, contract negotiation times)

-

Innovation outcomes (supplier-driven product or process innovations)

-

Stakeholder satisfaction (internal teams, end customers)

-

What are the examples of successful supplier sourcing strategies?

Successful supplier sourcing strategies include Toyota’s just-in-time partnerships, Apple’s dual global sourcing, Unilever’s sustainable sourcing, Walmart’s cost-driven partnerships, Starbucks’ ethical coffee sourcing, and Tesla’s direct raw material contracts. These approaches show how efficiency, resilience, sustainability, and cost optimization help companies strengthen supply chains and maintain competitive advantage.

What are the example of strategic sourcing principles?

An example of strategic sourcing principles is Apple’s supplier diversification strategy. Instead of relying on a single vendor, Apple uses multiple global suppliers for key components like chips and displays. This follows principles of risk mitigation, cost efficiency, and supplier collaboration, ensuring business continuity and consistent product quality.

Schedule a Demo

We’d love to hear from you. Please give us a call on +1 315-645-2799.

Explore more from Procol

Discover expert tips, how-to guides, industry insights, and the latest procurement trends.

How to Achieve Procurement Cost Savings: Complete Guide & Strategies

Procurement cost savings represent financial benefits achieved through strategic purchasing and...

Procurement orchestration: All you need to know in 2026

Explore the value of procurement orchestration, how it works, its benefits,...

Top 22 spend management KPIs to optimize procurement in 2026

Today’s business world has moved from just ‘buying’ to ‘managing spend’...